Intro

You may know that threads are what provide screws with their unmatched grip strength and keep your materials firmly together, locking the wood in place. However, what you may be less aware of is just how many different thread styles, shapes and types are available. This guide will take you through the most common screw threads and what applications they tackle best, as well as explore some lesser-known thread styles.

If you need help dissecting what different threads, heads and gauges do, take a look through our other Screw guide pages:

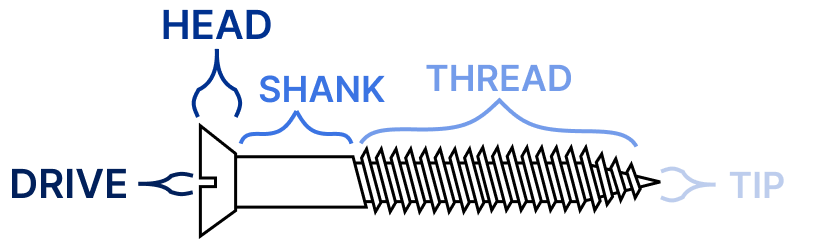

Screw Anatomy

Before we take a look at the different types of screws, it's a good idea to get acquainted with their different parts first:

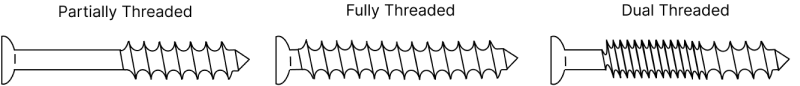

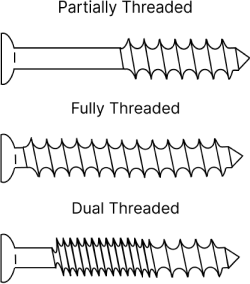

Screw Threads: Partially, Fully or Dual

All screws have ‘threads’, which are the helical shape that runs around the cylinder of the screw. However, not all screw threads are going to work with all applications; each one is specifically tailored to a different task or material. Factors such as whether the screw is partially, fully or even dual threaded can all impact the outcome of your fastening job:

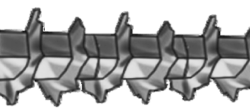

1) Partially-threaded Screws

- This external threading only runs partially down the shaft

- Used for extreme holding force

- Ideal for when precision and alignment is vital

- These screws have less weak points that could lead to bending or cracking

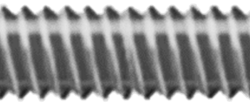

2) Fully-threaded Screws

- Fully-threaded Screws

- This external threading runs all the way down the shaft

- Used for where grip strength is critical

- Can withstand greater forces than partially-threaded screws

- Rarely shear and tend not to loosen as much

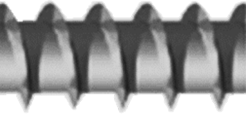

3) Dual-threaded Screws

- Has a double start thread running along the body of the screw

- They often have a larger pitch, or TPI (threads per pitch)

- They can be inserted or removed twice as fast as a single-start thread

- Able to hold material together more securely

Common Screw Threads

Some threads have sharp designs meant for drilling directly into softer materials, such as wood, however, others will require a pre-drilled hole, such as those going into masonry. By paying attention to these characteristics, you can ensure that your choice of screw is going to provide you with the most appropriate strength for the project at hand.

Below are some of the most common screw thread types:

Screw Thread Chart

If you’d like to understand more about screw threads, including information on thread protection or formulas to determine a thread’s strength, check out this helpful PDF Document from the Fastenal Engineering & Design Society.

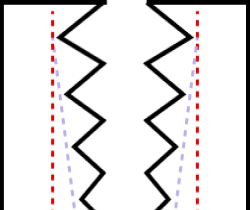

Parallel VS Tapered Threads

There are two main profiles that appear on fasteners in terms of their threads: parallel and tapered. The thread titles may seem self-explanatory, and thankfully when dealing with screws this aspect is already decided in the screw type, but it's still important to note for pre-drilling purposes (parallel threads may need more pre-drilling than tampered ones)