Intro

When it comes to deciding how long a screw should be, you can often find yourself playing a bit of a guessing game - however, the single most significant factor that will determine the strength of your fastening job is the screw’s length, so it's worth taking the time to do your research. Other factors, such as a screw’s tip or gauge, won’t make or break the job at hand and the differences are often nugatory, however, if you want to avoid pre-drilling, a specialised screw tip will have to be chosen (namely a self-drilling screw). This guide will tackle the questions regarding these screw features, such as how to measure a screw, what is a screw gauge and what applications different tip styles are built to handle.

If you need help dissecting what different threads, heads and gauges do, take a look through our other Screw guide pages:

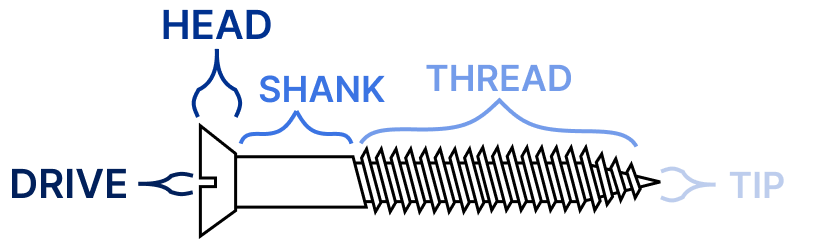

Screw Anatomy

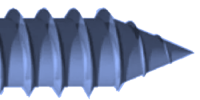

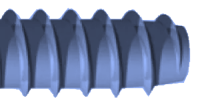

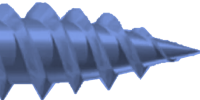

Before we take a look at the different types of screws, it's a good idea to get acquainted with their different parts first:

How to Measure a Screw

Measuring the length of your screw is a crucial step in ensuring that your materials are going to hold fast together; if your screws are too short they may not even reach your second material, or provide a weak, flimsy hold if they do. However, if your screws are too long, they risk not tightening down properly - or even worse: poking through to the other side.

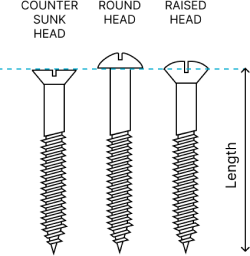

The length of the screw is measured from the tip of the thread to where the head sits flat, though this can be a little tricky as you have to take into account what screw head you’re using as different style heads will rest differently on surfaces, as shown in the diagram below:

Deciding Screw Length

There are no strict rules set in place to govern the size of screw you should be using, but the typical rule of thumb is that the screw should go through at least half the thickness of the bottom material, e.g. ¾” into a 2x4. There are some other general tips that are helpful to follow:

- It should not be long enough to go right through the materials you’re fastening.

- It should not be thick enough to split the materials you’re fastening.

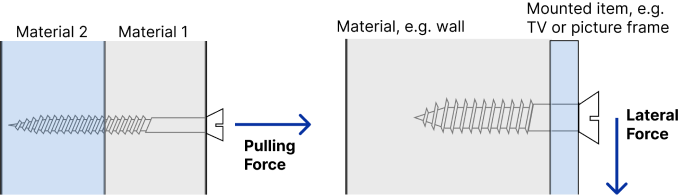

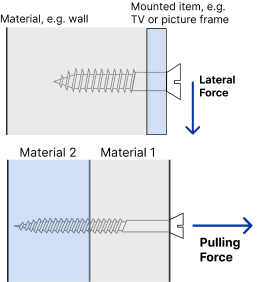

- If you need pulling force, use a longer screw with more thread.

- If you need lateral force, use a thicker screw.

Tip: When measuring the length of screws, the technical term for the overall measurement of the screw is called the effective length.

Tip: When measuring the length of screws, the technical term for the overall measurement of the screw is called the effective length.

What is Screw Gauge

The gauge of a screw refers to the diameter of its shank (the unthreaded part) and can be anywhere from 1 to 16 - the larger the number, the larger the diameter of the screw will be.

The following metric to imperial conversions are widely accepted as the UK industry norm:

What number you select is dependent on whatever material you’re working with, but generally…

- Very thick or heavy materials: #12-14

- For general, average materials: #8

- For finer materials: #4

Tip: The imperial gauge range can be traced back to the industrial revolution and was used throughout the British Empire for many years!

Tip: The imperial gauge range can be traced back to the industrial revolution and was used throughout the British Empire for many years!

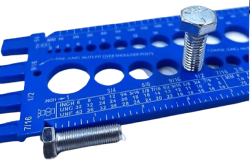

How to Measure Screw Gauge

In the UK, the screw gauge - or ‘diameter’ of the shank is roughly half the size of the screw head, and as stated above, most of the time a #8 will suffice - the most important factor in choosing your screw is the length, not the gauge, so don’t worry about this too much. However, if you’d like to be more specific and measure your screw diameter, there are two main ways to do this: