How are bricks made?

Manufacturers know how to make bricks of the highest quality. Therefore, all brickwork should be made with professionally produced bricks. The way different bricks are created affects their properties. A normal brick will approximately contain 50% sand, 30% clay, 5% lime, ≤ 7% iron oxide, and less than 1% of magnesia. However, different coloured bricks contain different mineral contents. For example, white bricks have more lime content, and rustic red bricks have a higher level of iron. Firing bricks at extremely high temperatures results in darker colours, such as browns and greys. Below are two common types of bricks and how they are made.

- How are engineering bricks made: this type of brick is made with high-quality clay and fired at extremely high temperatures under great pressure. Solid blue engineering bricks are made by firing clay bricks at higher temperatures with low oxygen. A stronger brick can be made by pressing the clay material with greater force and firing it for a longer period.

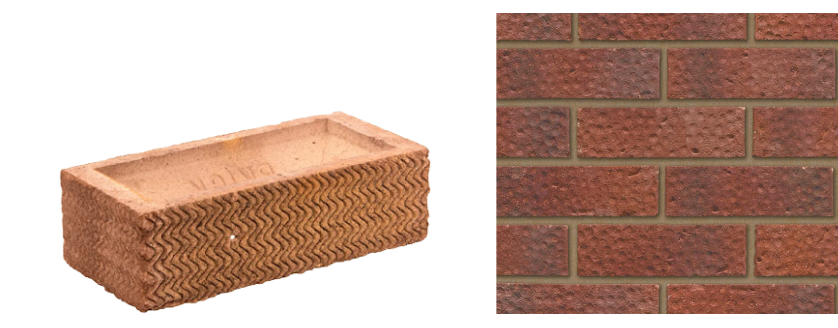

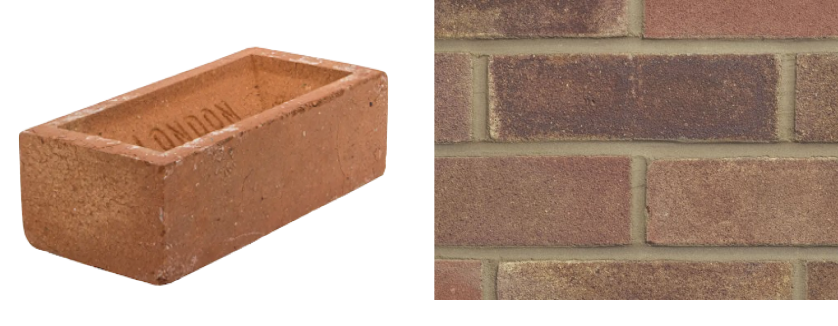

- How are facing bricks made: Extruded facing bricks are made by forcing brick clay through a brick die to create a long length of material, then cutting it into manageable sizes called slugs which are approximately 1.5m in length. These slugs are then cut to the correct size by a wire. The wirecut bricks are then hardened by drying them at high temperatures before being fired. Pressed facing bricks are made by forcing clay into a mould and being fired at a high temperature, with pigments added to provide a variety of finishes. Soft mud facing bricks can be made by hand, with a person manually pushing the clay brick mixture into a mould instead of a machine.

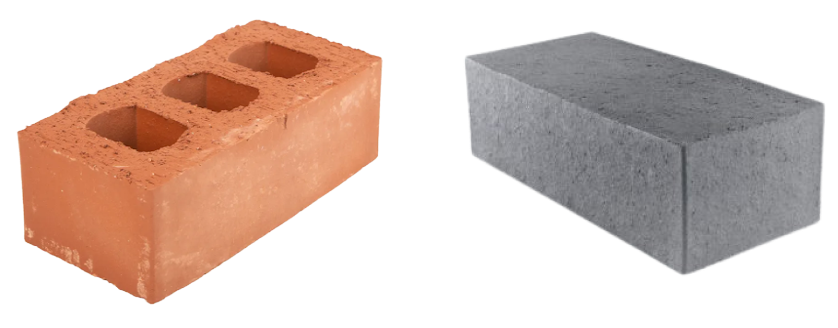

Engineering bricks

Engineering bricks have high compressive strength, low water absorption, and acid resistance. Their purpose is to provide strong structural support, withstand any weather conditions or water contact, and last a long time. They are easily identifiable by the holes that run through their top and bottom and their smooth finish. These holes increase the strength of the brickwork by allowing the bricks to become locked together via the mortar that fills and connects them.

Facing bricks

What are facing bricks?

Facing bricks, also called face bricks, are usually seen on the exterior of buildings. These bricks are designed to be weather resistant and visually pleasing. They come in a variety of colours and textures, providing a neat appearance and fire resistance.

There are two types of facing bricks - extruded and soft mud.

- Extruded bricks, also called wire-cut bricks, can be produced quickly by a manufacturer. This type of brick is more consistent in appearance and size than handmade bricks.

- Soft mud bricks, also known as stock bricks, provide a traditional and older appearance. This type of facing brick can be made by hand and is primarily for decorative use

Common bricks

What are common bricks?

Contrary to their name, these bricks are not as frequently used as facing or engineering bricks. Common bricks have a lower quality than other brick types. They have a moderate amount of compressive strength, vary in appearance, and cannot be used underground. Common bricks are made using basic brick clay with no added surface treatments or colour-specific pigments (and can also be made of concrete).

What are common bricks used for?

They are mostly used for inside brickwork where they will be plastered over and unseen. However, they can be used as wall bricks, and in other general construction projects where the structural quality of the brick is essential but not the look. This makes them good to use as retaining wall bricks.

How many common bricks in a pallet?

The average is 500 common bricks per pallet, but pack size greatly ranges between 300 to 600 bricks.

How much are common bricks?

As common bricks have no distinct aesthetic qualities and less compressive strength than engineering bricks, they are cheap in comparison. Common bricks can be purchased from as little as 40p each, with £2 being on the higher end of the pricing range. Concrete common bricks are normally the cheapest type. (Pricing range calculated September 2022)

Brick comparison table

If you are unsure which type of brick to buy, local brick suppliers and building material suppliers are always happy to help.

Frequently asked questions

Air bricks, often referred to as air vents, have many holes all the way through them. They are used for cavity wall and sub-floor ventilation to prevent dampness. This type of brick can be made of clay, metal, or plastic, with clay air bricks being the traditional kind. When they are required, these bricks need to be kept clear of debris such as dead leaves, and not blocked up. To avoid pests from entering properties via air bricks, special mesh to cover air bricks can be purchased. Air brick regulations are set out by the NHBC in relation to ventilation and damp proofing, more about this topic can be found in their ‘Air bricks to underfloor’ guide

How to Lay a Brick Path

Materials you will need:

- Bricks: Choose the type, size, and colour of bricks that suit your aesthetic preferences and the area's requirements.

- Shovel: For digging the area and levelling the ground.

- Gravel: For creating a stable base.

- Sand: For levelling and filling gaps between bricks.

- Pointed timber pegs and string: For marking the area and ensuring straight lines.

- Rubber mallet: For settling the bricks in place.

- Tamper: For compacting the base material.

- Spirit Level: To ensure the bricks are laid evenly.

- Safety gear: Safety gloves, safety goggles, and knee pads.

Steps:

- Plan and measure: Determine the area you want to pave with bricks and mark it with wooden stakes and string. Measure the dimensions accurately.

- Excavate the area: Use a shovel to remove the top layer of soil and any existing vegetation. Dig to a depth that allows for the thickness of the bricks, plus a stable base. Typically, a depth of 4-6 inches (10-15 cm) is sufficient.

- Create a stable base: Fill the excavated area with gravel to create a stable base. Add the gravel in layers, and use a tamper to compact each layer to ensure a solid foundation.

- Add a layer of sand: Spread a layer of sand over the compacted gravel. This will help level the bricks and provide a smooth surface for laying them.

- Start laying bricks: Begin laying the bricks from one corner or edge of the area and work your way across. Make sure the bricks are placed tightly together to avoid large gaps.

- Check for level and alignment: Use a level and string to ensure that the bricks are laid evenly and in straight lines. Adjust the sand underneath the bricks as needed to achieve a level surface.

- Fill gaps with sand: Once all the bricks are in place, spread sand over the surface and use a broom to sweep it into the gaps between the bricks. This will help stabilize the bricks and prevent them from shifting.

- Compact the pavement: Use a tamper to gently compact the entire brick pavement. This will settle the bricks into the sand and create a more stable surface.

- Add finishing touches: Sweep off any excess sand from the surface and hose down the pavement to help the sand settle into the gaps. You can also add an edge restraint, like concrete or plastic, to keep the bricks in place.

Advantages of using brick

- Sustainable - bricks last hundreds of years when maintained and laid correctly. They are also usually made using sustainable practices, with very little waste being created in the process. It is also easy to recycle bricks, with reclaimed bricks (second hand bricks), being a sustainable building option. Buildings have to meet energy performance regulations, including Part L, which concerns brickwork. To learn more, check out Gov UK’s statutory guidance.

- Can increase property sale price - well-maintained brickwork or the use of interesting and attractive facing bricks can help increase the value of a property, compared to render or wood siding homes. This is because brickwork is energy efficient and durable.

- Aesthetically pleasing - facing bricks come in all kinds of colours, sizes, and shapes, allowing interesting architecture to be created.

- Fire resistance - many bricks can withstand extremely high temperatures and do not contribute to the spread of fires. Fire bricks also called refractory bricks, fireplace bricks or kiln bricks, in particular, are used for creating fireplaces, chimneys, cooking chambers, and more. This type of brick is designed to endure even higher temperatures before it starts to deteriorate.

- Thermal insulation - Facing bricks are usually made of clay and are energy efficient. These bricks absorb and release heat slowly, helping regulate a property’s temperature.

- Low maintenance - brickwork is extremely enduring and rarely requires maintenance