Intro

Plywood is constructed using only two materials; wood veneers and glue. Based on the interaction of the two, performance of plywood can then be determined. For information on how several layers of hardwood or softwood veneers are glued together, see our types of plywood guide page. Here, we will be talking about important individual standards for plywood in order for it to be installed and used in construction. To meet these standards, plywood is subjected to testing and it is classed accordingly; for example for strictly interior application or for more durable exterior applications.

UK and EU Standards for Plywood

Plywood is often sourced and manufactured overseas. Plywood standards refer to the British Standard and Code of Practice for installing and using plywood in the UK. Following Brexit, the UK has adopted the same EU standards for using plywood in the construction industry. A plywood manufacturer must legally comply with minimum safety and procedural requirements known as UK designed or European harmonised standards. Therefore, plywood undergoes testing that determines which plywood can be used under different conditions. These tests will determine the class the plywood is graded into.

- Plywood Bonding Quality (BS) EN314

Bonds are used to produce plywood that determine three classes based on test requirements that the plywood bond must meet. In these tests, plywood boards are being subjected to imitated weather conditions. The bond class will then be specified based on the quality of the plywood bonds.

| Class | Application |

|---|---|

| Class 1 | Dry conditions (interior) |

| Class 2 | Humid conditions (protected/limited exterior, damp interior) |

| Class 2 | High humidity conditions (exterior) |

- Plywood Performance Specifications (BS) EN636

After the bond class has been established, plywood undergoes further testing to determine its performance class for the construction industry. This standard gives requirements for plywood use in general purpose (non-structural) and structural applications. There are three plywood classes that take into account both the quality of the bond and the durability of the timber species.

| Application | Plywood Class | Service Class | For End Use In |

|---|---|---|---|

| Dry conditions (interior) | EN636-1 | Class 1 - interior climates | Interior walls, floors and interior (warm) roofs |

| Humid conditions (protected/limited exterior, damp interior) | EN636-2 | Class 2 - protected exterior and humid interior applications | Ground floors, exterior walls and exterior (cold) roofs |

| High humidity conditions (exterior) | EN636-3 | Class 3 - designed for exposure to weather over long periods | Exterior for construction purposes |

Is Plywood Waterproof?

There is no waterproof plywood specifically. The term usually refers to plywood produced using a type of weatherproof adhesive. Plywood that has been classified to be suitable for exterior use will not deteriorate over time in wet conditions. However, it is not totally waterproof as the wood veneers can still be affected by water.

Sealing plywood on all faces and edges is vital for plywood specified for use in humid and exterior conditions. This limits the moisture from accessing it, making it more long lasting!

Sealing plywood on all faces and edges is vital for plywood specified for use in humid and exterior conditions. This limits the moisture from accessing it, making it more long lasting!

What is WBP Plywood?

WBP plywood is a term used in the plywood industry by professionals. It stands for weather and boil proof meaning the plywood can be used in harsh weather conditions. This makes it very durable because it has been produced using a type of adhesive to glue the wood veneers together, preventing the plywood layers from breaking apart. The most common WBP glue is melamine or phenolic glue. Furthermore, in order for the plywood to be fully suitable for exterior use, it needs to conform to the EN636 performance standards and service classes.

Marine Plywood BS1088

BS1088 is the British Standard set for marine plywood. All marine ply needs to be manufactured to meet the standard that is tested by Lloyd’s Register in Britain. The construction of marine plywood needs to ensure endurance in high humidity conditions. This is achieved by the cross-lamination process of pressing layers of veneer together at right perpendicular angle at 90 degree Celsius giving the material extra strength. To begin with, the structure of the panels must be chemically untreated hardwood veneers combined with solid and knot-free surfaces and finally bonded with WBP glue to make a high quality marine grade plywood for prolonged exterior use.

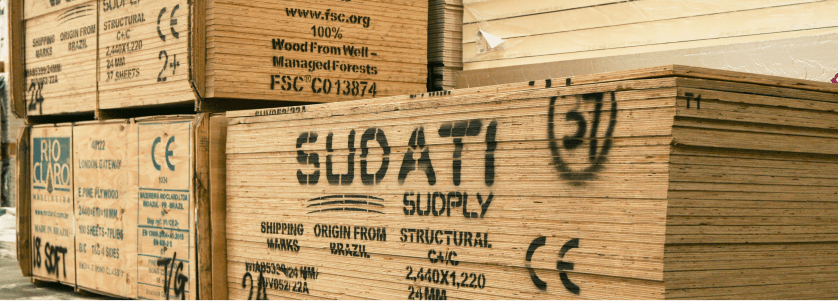

Plywood Certification System

From January 2023 plywood manufacturers from outside the UK wishing to supply the UK market, must change the approved body from EU certification to a separate UK Approved Body. They assess and certify goods for the UK market. Plywood manufacturers wishing to supply both the EU and UK markets will need to be assessed separately from January 2023.

Mark of Approvals

- CE Mark - Wood that enters EU countries use the CE Mark from EU Notified Body System

- UKCA - UK Conformity Assessed marking is for wood coming into England, Scotland and Wales

- UKNI - UK Conformity Assessed marking is for wood coming into Northern Ireland alongside the UKCA