Engineered Wood Flooring Guide

Engineered Wood Flooring is a great alternative to solid wood flooring. It's less susceptible to moisture and can be used in almost all areas of the home.

Contents

Intro

Engineered wood flooring has a lot of similarities to solid wood flooring in terms of the look and design. The difference is in the functionality because engineered wood is less susceptible to moisture and can be used in areas where solid wood is not appropriate such as kitchens, conservatories and basements.

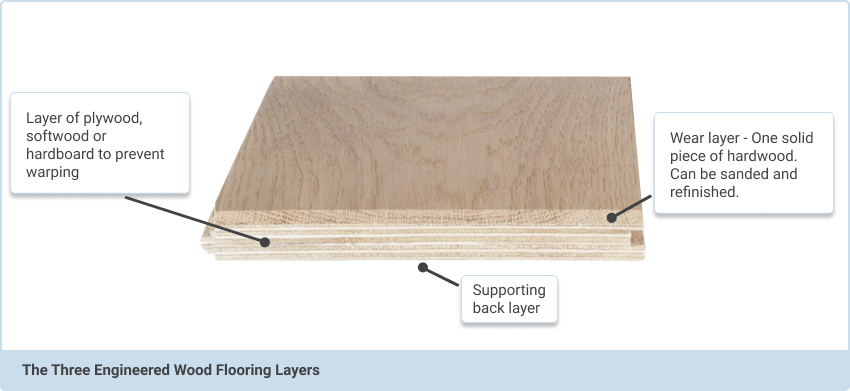

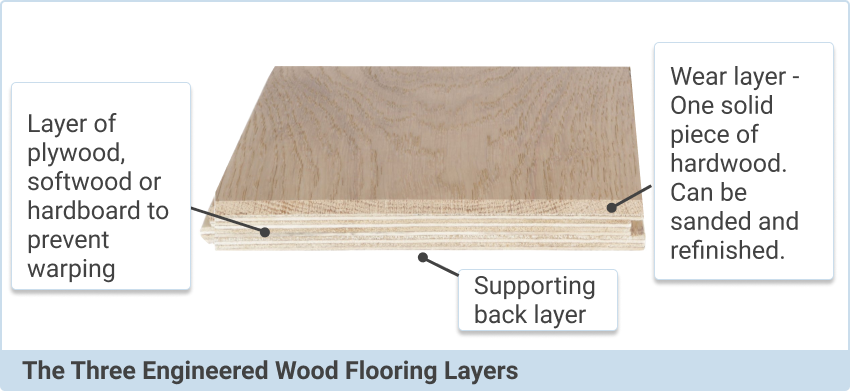

Engineered flooring is constructed with layers of both hardwood and plywood, softwood or hardboard.

Solid and engineered wood have a similar look because the top layer is always made of one solid piece of hardwood followed by a second stronger layer of plywood, softwood or hardboard. This layer prevents the board from warping. At the bottom of the board there is a supporting back layer.

How Does Engineered Wood Flooring Compare?

| Engineered Wood | Solid Wood | Laminate | Vinyl | |

|---|---|---|---|---|

| Hardwearing | 3 | 2 | 4 | 5 |

| Maintenance | 4 | 5 | 1 | 1 |

| Initial Cost | 4 | 5 | 2 | 3 |

| Refinish | ||||

| Longevity | 4 | 5 | 3 | 3 |

| Easy to Clean | 2 | 2 | 4 | 5 |

| Water Resistant | ||||

| Underfloor Heating | 5* | 1 | 4 | 4 |

Key

![]() Suitable

Suitable

![]() Not Suitable

Not Suitable

*subject to floor thickness/manufacturer

(1-5) rated least to most

Room Suitability

Engineered wood floor is suitable for most areas in your home. It looks especially stunning in living areas and performs well in this area of the house due to low moisture and steady temperatures. You can also install engineered flooring in a kitchen. However, be mindful to wipe away any spillages and dry your floor off as quickly as possible to prevent any damage and the water seeping in between the boards.

Engineered floors are not resistant to water. When it comes to the finish on top of your flooring board, a lacquered option offers more durability for kitchens. We do not recommend engineered wooden flooring for bathrooms as it is vulnerable to splashes and changes in temperature.

You can easily create the illusion of wood in these rooms with waterproof laminate or vinyl flooring that both come in wood effect design options.

Engineered wood floors are also suitable for conservatories or basements because they are less prone to expanding or shrinking. The same goes for underfloor heating making engineered wood the perfect option to warm up your flooring. Engineered wood is best to use with underfloor heating as it performs well with changes in floor temperature.

Suitable Areas

![]() Living Spaces

Living Spaces

![]() Kitchens

Kitchens

![]() Conservatories

Conservatories

![]() Basements

Basements

![]() Stairs

Stairs

Unsuitable Areas

![]() Bathrooms

Bathrooms

Engineered Wood Thickness & Width

Engineered wood flooring can last a long time because it can be sanded down and refinished just like solid wood. The number of times it can be sanded depends on the thickness of the board and its hardwood wear layer. Engineered boards generally come in thickness of between 7mm to 22mm. The thicker the board the thicker the wear layer for greater longevity. If you have underfloor heating, it is important to note thickness increases heat up time. In general, 20mm is the maximum thickness that is recommended so that the floorboards do not block the heat entirely.

Engineered boards range in width from 125mm to 300mm giving you a variety of options for smaller or bigger rooms. The width is an important factor to consider when it comes to the overall look of the room. If you choose smaller boards for smaller rooms, it can create an effect making the room look bigger. Wider boards are better for larger rooms.

Engineered Wood Species & Colours

Many engineered floors are made of oak wood species. Oak flooring is certainly the most popular and traditional choice of wood and there is a wide selection in a range of different colours from light to dark stain to suit your requirements.

Walnut provides a rich and dark alternative. The warm colour of American black walnut flooring brings a touch of luxury to any home making it a different design option to oak wood flooring.

There are plenty more species of engineered oak flooring including ash, beech, jatoba, maple, cherry and jarrah to name a few. These and plenty more options are available to view in well stocked flooring showrooms.

Engineered Wood Grading & Style

Rustic grade is the most popular wood grain available. Rustic grading allows for medium to large size knots and variations in grain and colour for the most natural look. Any splits, streaks or holes in the wood is filled with wood filler keeping the surface smooth and even. For a cleaner board there is also natural and rustic grade engineered flooring available with less colour variation.

Single strip floors are the most popular style of engineered flooring. This creates a classic look from a single piece of wood from a tree made into a board and is the most simple design option that makes your room look as spacious as possible. Multi strip boards offer a different style and finish, they are made from smaller cuts of wood combined into a single board. There are also newly popular herringbone pattern designs available that are also called engineered parquet floors. Herringbone flooring is made from small blocks laid in a geometrical pattern creating a stylish look for your space.

Engineered Wood Edging Options

The edging style on engineered floor boards depends on the kind of look you wish to achieve. Engineered wood floor that has square edge styled planks is even and smooth whereas all bevelled edged boards also have a deep v-groove on 2 or all 4 sides of the board. To balance out both of these edging options microbevels have been created to minimise the gaps between the boards whilst still have slight definition for a traditional look.

Square Edge

Engineered wood floor that has square edge styled planks is even and smooth, looks more modern and allows for easy maintenance care.

Bevelled Edge

Bevelled edges can create a more traditional look in your home. The bevelled edge engineered boards can help hide any tiny gaps between the boards which might appear over time.

Microbevelled Edge

Microbevelled edges can also create a more traditional look in your home with minimal bevels between the boards.

Engineered Flooring Finishes

Overall, engineered wood floors are highly durable especially when covered in hard wearing lacquer treatment. Lacquer finish also prevents scratches and offers greater moisture resistance.

There are two types of lacquer finishes each giving slightly different coating to your floor:

- Satin lacquer gives a smooth glossy finish.

- Matt lacquer can look more natural with less gloss. Matt finish actually looks similar to an oiled finish but comes with the added benefit of being harder wearing. This is the most popular choice of finish.

Alternatively and the most natural look you can opt for is an oiled finish that can easily be reapplied over time. This gives the most classic finish to your engineered wood floor.

How to Lay Engineered Wood Flooring?

Installing engineered flooring can be relatively easy and quick. If you want to do this yourself please see the full installation manuals for each engineered wood flooring product. If you are not confident please ensure the flooring is installed by an experienced floor fitter or other competent professional.

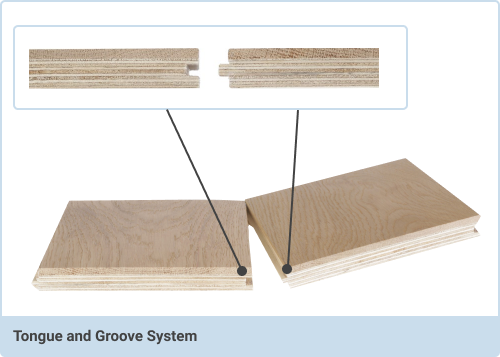

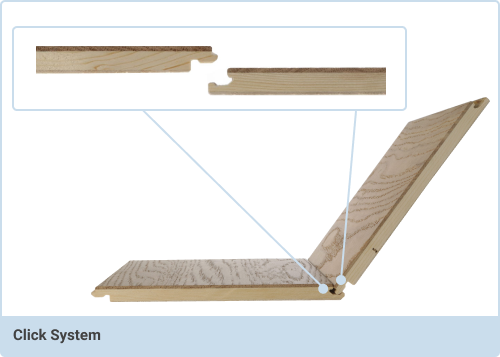

Installing

All engineered floors come in either tongue & groove or click installation method. The tongue & groove method is more tricky and you should consider a qualified floor fitter, whereas the click system can be installed through DIY. First you will need to lay wood underlay if you opt for a floating installation. Alternatively you can lay tongue & groove engineered wood flooring by screwing it down to a subfloor with wood screws or by gluing it using wood floor adhesive. You can use underlay with tongue and groove if you are glueing the edges of the board in which case we recommend adding the glue into the groove not the tongue for a stronger grip.

Acclimatising

Before you get your engineered wood flooring installed you will need to acclimatise the boards by opening the box and leaving them in the middle of the room for a minimum of 2 days but preferably even longer between 5-7 days. This is so the boards have time to get used to the new conditions in your home. The room should be kept at a steady, normal temperature. When acclimatising engineered wood flooring for underfloor heating you should lay each box individually on the ground and start your heating system at a low setting. Slowly increase the setting by 2 deg every 2 days working it gradually up to the highest setting that you are likely to require. Once reached, reduce the heating by 2 deg every 2 days down to the lowest level of heat that is comfortable. This process should be maintained for a minimum of 2 weeks to acclimatise the engineered floor correctly for underfloor heating.

Preparation

Please also make sure your subfloor is clean and dry before installation. You will need to remember to leave 10-12mm expansion gaps around the room because wooden boards can expand widthways if the temperature gets too high. The expansion gaps should therefore always be left widthways and not lengthways in the room. You will also need a gap around pipes and flooring trim can easily be used to efficiently hide these gaps. Always work from 2-3 boxes at a time to get the best natural colour mix.

How to Clean Engineered Wood Flooring?

Thanks to its multilayer construction engineered wood flooring is very durable and can withstand high levels of wear and tear. However, maintaining it means it keeps looking its best. Always use a cleaning product recommended for wood flooring and follow the instructions on the label. Many times the manufacturer has its own recommended cleaning products so make sure you check these out. Once a week mopping is sufficient along with hoovering or sweeping. Make sure the mop is well wrung out.

Be mindful of dragging heavy furniture or any sharp objects such as stiletto heels along the boards as this can cause damage to the texture of the flooring. For daily protection we recommend rugs and mats especially by door entrances and always using felt pads on all furniture legs that sit on the floor to avoid scratches. Wipe away any puddles that can cause damage to the wood floor immediately with a damp cloth or a mop. Whilst engineered floor is splash resistant thanks to its finish, it is not capable of handling high levels of moisture.

Overall, engineered wood flooring is easy to maintain and with these regular upkeep tips you can enjoy your engineered wood floor for a long time. From time to time you may wish to repolish the floor for extra durability. An oiled surface for example can be recoated, making your floor look as good as new. For a lacquered surface you will need to use wax.